Leak Testing for EVs / HEVs Battery Pack

ü Battery cooling circuit – Glycol water solution

ü Battey cooling circuit - Refrigerant

ü External integrity of battery pack housing

ü IP67/ IP68 / IP69k

ü Gas: Air / Nitrogen / Hydrogen / Helium / Vacuum

ü Origin: USA

- Thông tin sản phẩm

- Tài liệu

Leak Testing for EVs / HEVs Battery Pack

#EVbattery #CoolingSysem #Automotive #Leaktestsystem

The production of batteries for electrically driven cars has recently ramped up significantly. It is very important to achieve a decent life time and performance of the battery in the new driven train technology as to not scare away any new users of this technology due to an initial bad experience. Typically battery cells are assembled into battery modules and then the modules are assembled into battery packs.

Both, the battery modules as well as the battery packs typically include some cooling channels which are operated either with a water-glycol mixture or with refrigerant which is by-passed from the AC system of the vehicle. In addition, the electronic module controlling the operation of the battery is usually also somehow cooled, again either with a water-glycol mixture or with refrigerant. Leak tightness is critical to avoid loss of water or refrigerant from the cooling system. For water-glycol cooling, typically leak rate of 10-3 mbar.l/s (0.06 sccm) are set as the threshold level. Refrigerant loops must be leak rate checked for leaks in ther 10-5 mabr.l/s range.

The complete battery pack is usually mounted in a housing. This housing usually must meet the IP67 standard are tested to leak rate in ther 5*10-3 mbar.l/s range.

|

System to be tested |

Specification |

Equivalent leak rate |

|

Battery cooling circuit – Glycol-water solution |

No significant loss of cooling fluid |

~ 10-3 mbar.l/s (~0.06 sccm) |

|

Battery cooling circuit – refrigerant |

No significant loss of cooling fluid |

~ 10-5 mbar.l/s (~ 5 g/a of refrigerant) |

|

External integrity of battery pack housing |

IP67 |

~ 5 * 10-3 mbar.l/s (~0.03 sccm) |

Hystrong has decades of experience working in the automotive manufacturing industry, and we understand the details of manufacturing check automotive components.

Test method for Cooling system

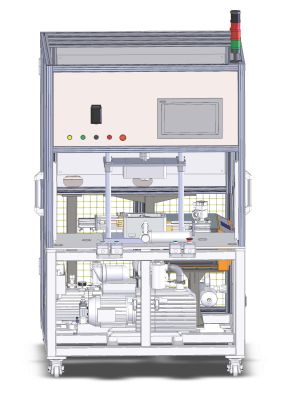

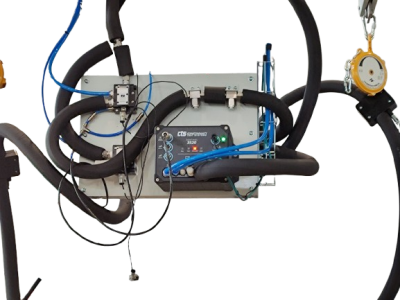

ü Pressure / Vacuum decay leak test: CTS Sentinel Serries

ü Hydrogen sniffing leak test: INFICON Sensistor Sentrac tester with Air or Forming gas (5% H2 & 95% N2)

ü Refrigerant sniffing leak test: INFICON HLD6000

ü Helium sniffing leak test: INFICON PROTEC P3000XL

ü Multi-Gas sniffing leak test: INFICON ECOTEC E3000 (Helium and Refrigerant)

Final leak test for battery pack housing

ü Accumulation Helium leak test

ü Sniffing leak test: Air or forming gas

Our Solutions are the Leak Testing Instruments of Choice for Automotive Manufacturers.

Leak testing is a critical part of your manufacturing process. Hystrong is a trusted partner to help you reduce cycle time, ensure accuracy, and control product quality.

Sản phẩm liên quan

Danh mục sản phẩm

Hỗ trợ trực tuyến

|

Hotline tư vấn Call/Zalo: 0919995040 |

|

|

Yêu cầu hỗ trợ Báo giá: Kỹ thuật: Hoannv@sumore.vn |